Production Line for Battery Tray of Electric Vehicles

AEE Lightweight focus on the development of all the processes of the battery tray technology for new energy electric vehicles, provide customers with a turnkey solution of the battery tray production line, and customize a full set of process solutions including laser welding, arc welding, spot welding, and glue coating , curing, cleaning, air-tight, stud welding, riveting, machining, and a series of battery tray processing and connection technology solutions.

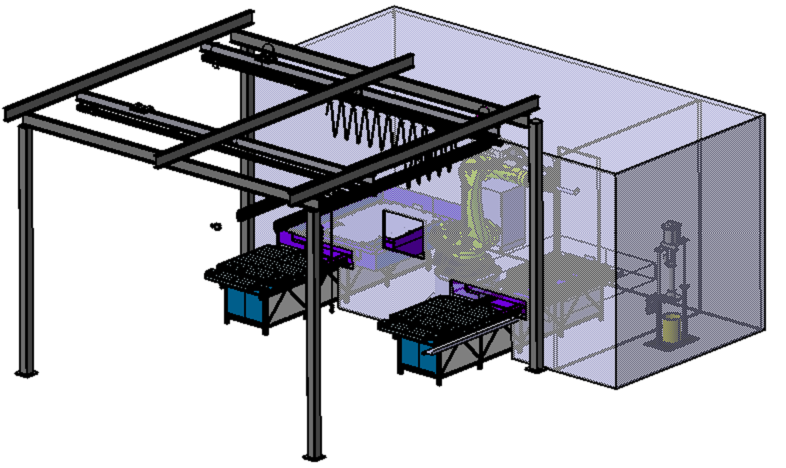

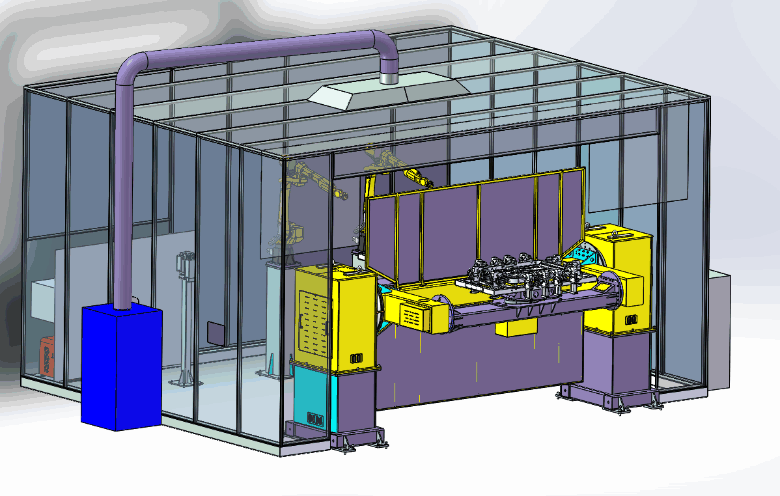

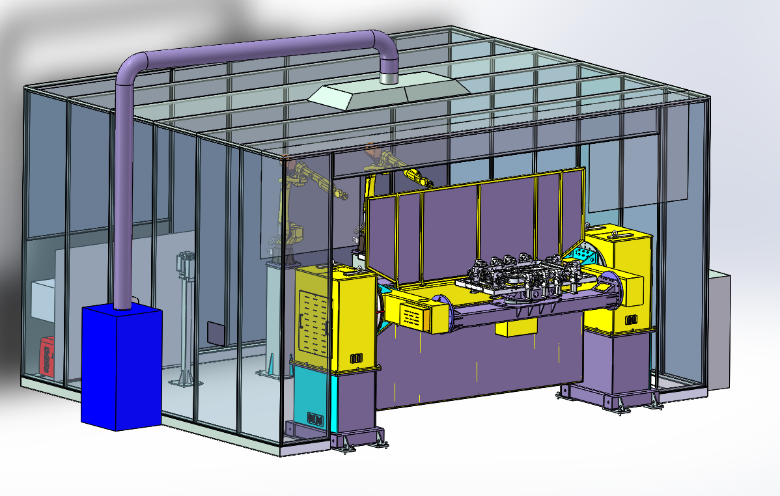

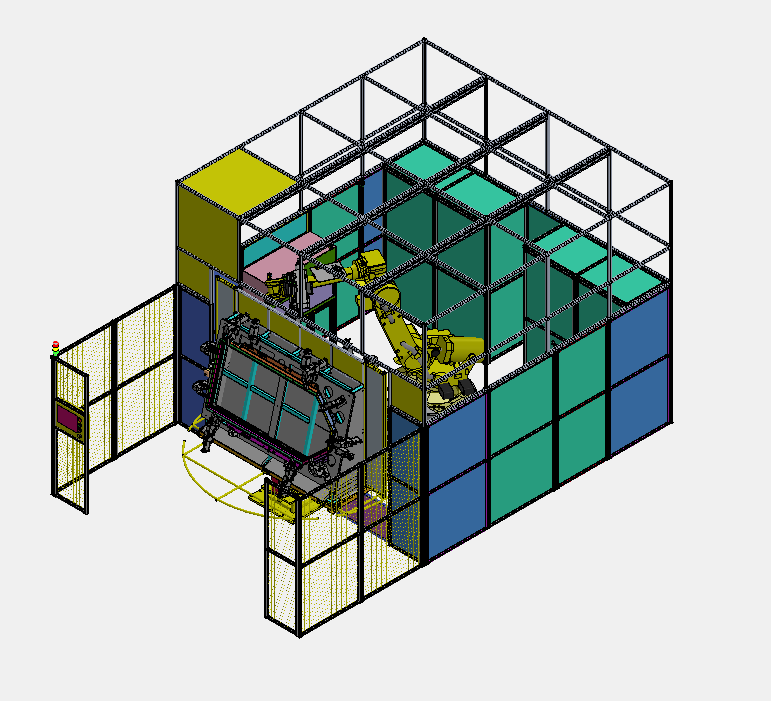

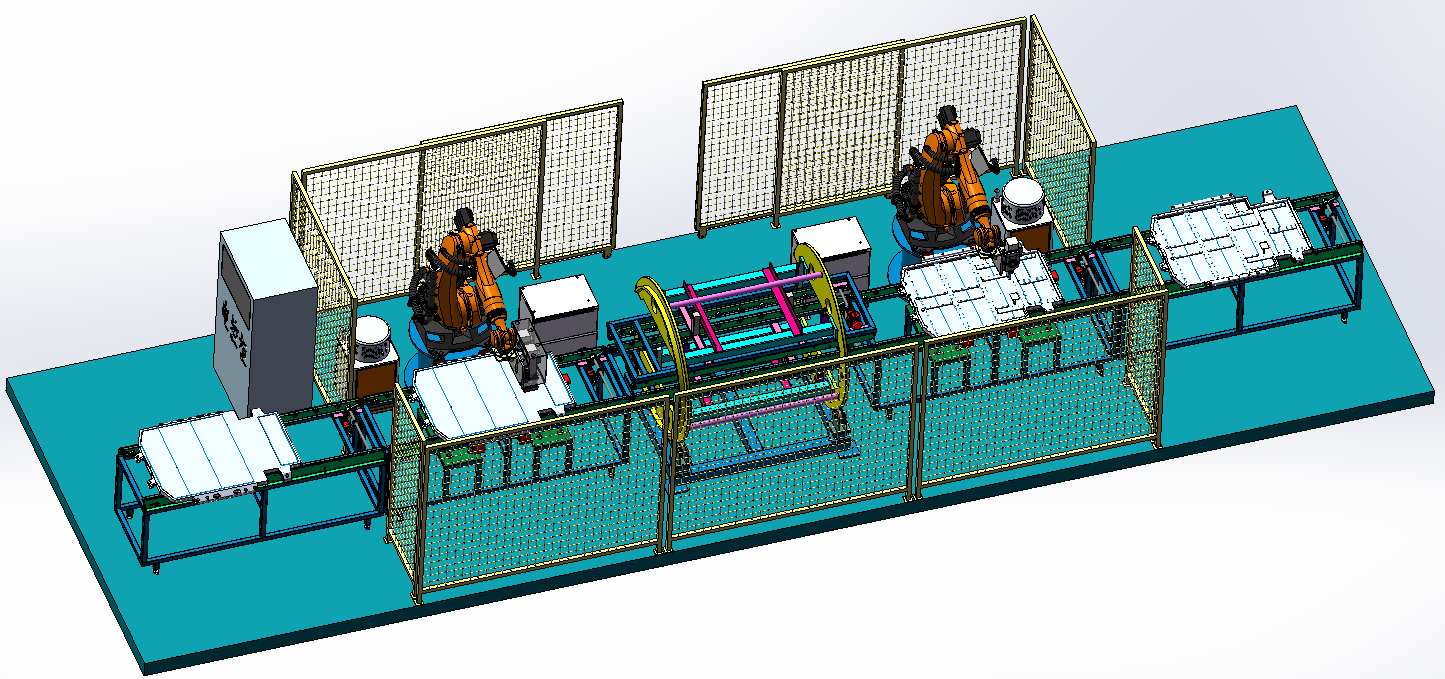

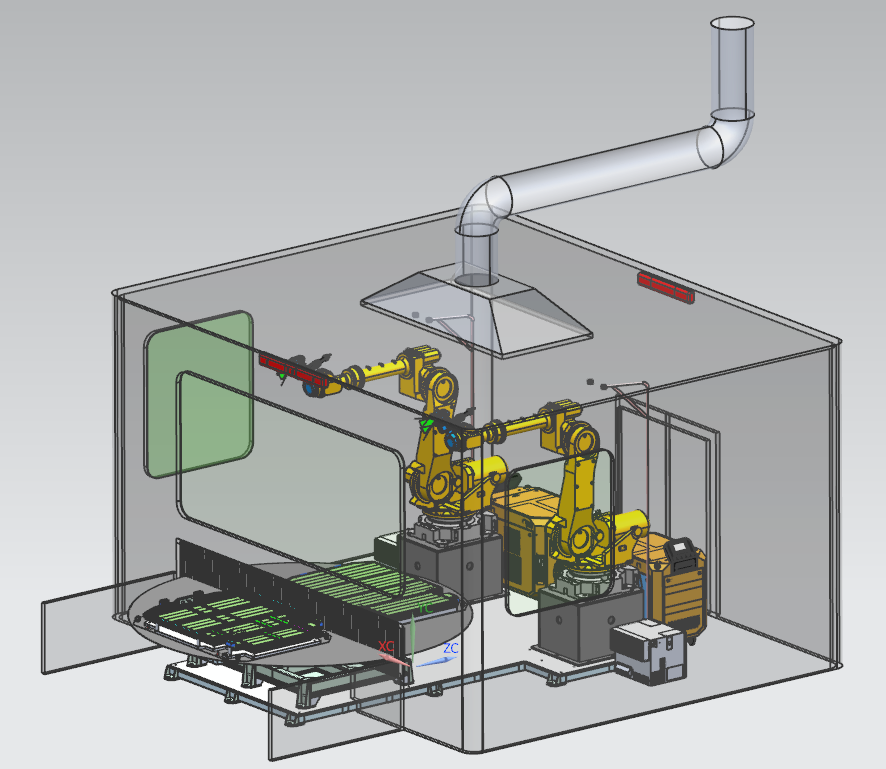

Robotic fusion welding workstation

n Application: welding of frame, bushing, beam and assembly

n Advantages: reduced personnel costs, improved weld quality, higher weld appearance and consistency, and improved worker operating environment

n Fume and dust are generated during the welding process, and a metal welding room is set up to centrally deal with welding fume and dust

n Positioner mode: single-axis single station, single-axis double station, three-axis double station and five-axis double station

n Robot installation method: conventional vertical, gantry upside down, slide rail upside down, etc.

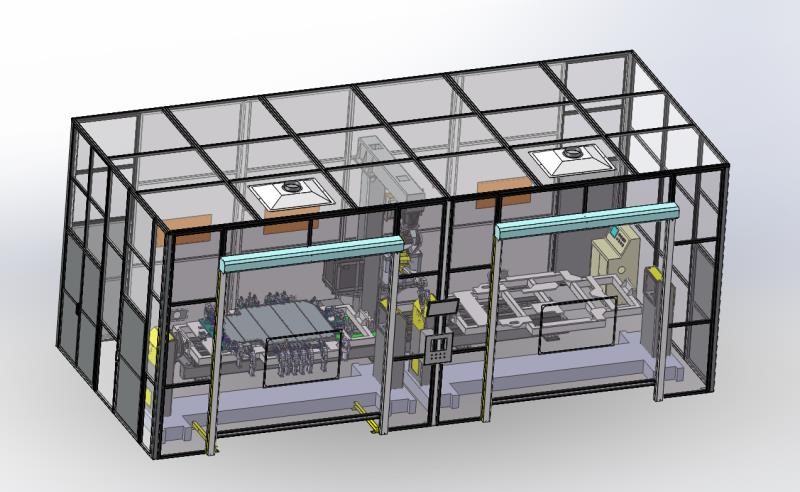

Robotic polishing workstation

Laser cleaning workstation

Robotic PVC workstation