AEE Best Bobbin Friction Stir Welding Suppliers in China

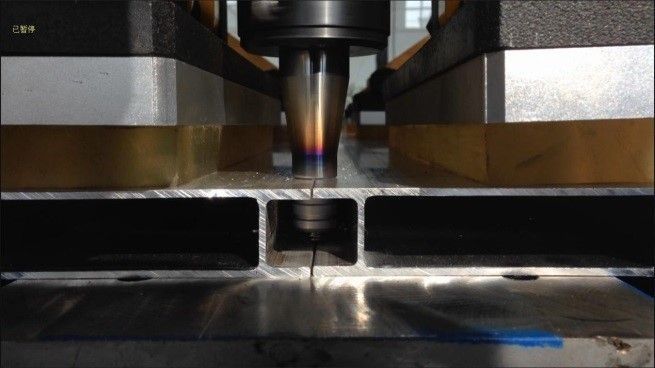

Bobbin Friction Stir Welding is a new type of friction stir welding method, compared with the traditional friction stir welding.

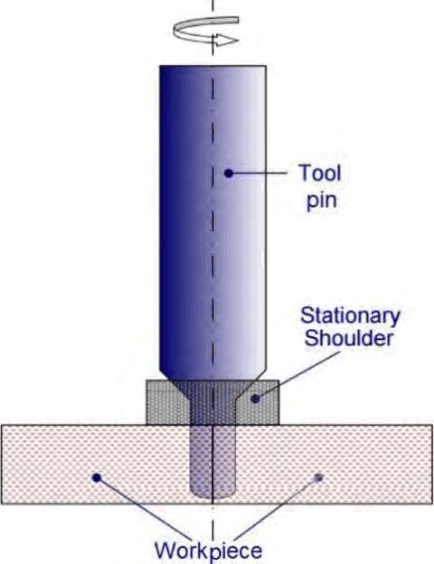

The bobbin FSW tool is designed with upper and lower shoulders, in which the lower shoulder can be used as a support plate during FSW process.

Bobbin Friction Stir Welding

It provides a feasible way for friction stir welding of complex structures or hollow cavities, and saves the cost of designing and manufacturing fixtures and pads.

Bobbin Friction Stir Welding has many of the inherent advantages of FSW, and at the same time can be realized without additional fixtures or rigid pads to weld the joint and obtain a joint with certain mechanical properties.

In addition, because Bobbin FSW welds the upper and lower surfaces of the weld seam at the same time, it also eliminates problems such as imperfections or root defects, which often occur in conventional friction stir welding.

In the field of rail transit vehicle manufacturing, lightweight aluminum alloy body has become an important development direction to reduce the energy consumption of rail vehicle operation.

Aiming at the hollow profile structure widely used in lightweight aluminum alloy car body.

The Bobbin FSW can be a good solution to the problem of the profile cavity can not be set in the pad, and improve the adaptability of friction stir welding to the structure, while reducing the manufacturing cost.

About Friction stir welding related products, more information can be found on the website: https://a-fsw.com/