AEE provides customer with optional features FSW tool

9 things about FSW tool optional features

Tool life monitoring system: The system is equipped with a FSW tool life monitoring system, which can automatically measure the length of the conventional FSW tool.

By setting the length parameter, detect the wear of the conventional FSW tool.

When the wear reaches the set threshold, the system will alarm and stop welding.

The tool setting device has an over stroke protection function to prevent accidental operation.

There is a dedicated window in the bottom right corner of the CNC system interface to display and set tool data.

Work-piece counting system: The system can record tool life and product processing quantity.

This function can display the number of program runs within a certain period of time on the control panel.

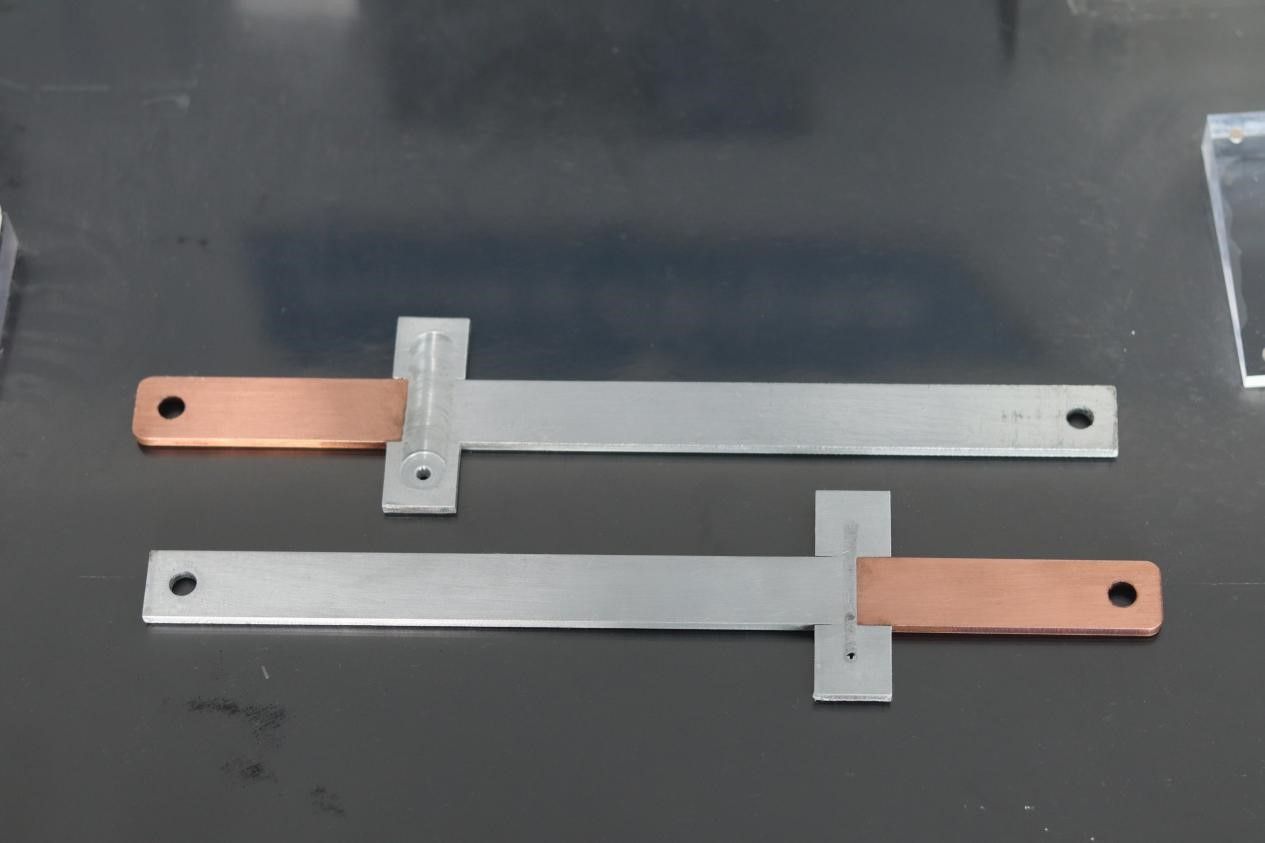

Welding demonstration function: The product debugging process references the welding demonstration function.

After the demonstration is completed, the program automatically records the welding trajectory of the product and adjusts it automatically for the same product.

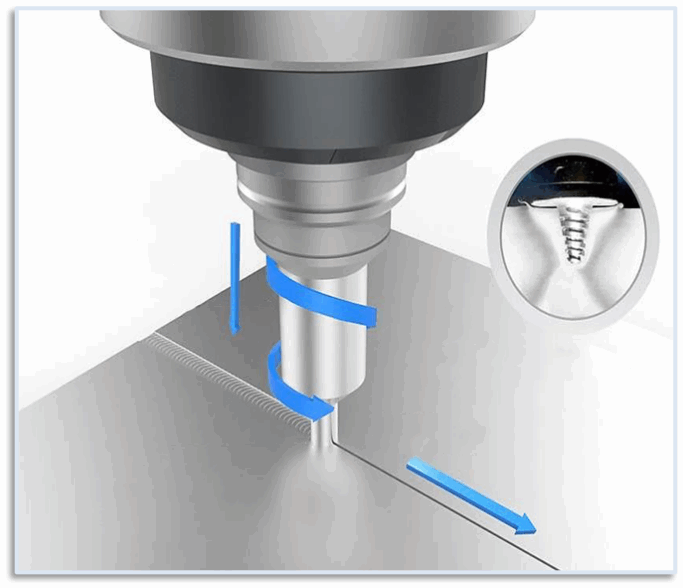

FSW tool

Welding force control system: The machine is equipped with a welding force control system to achieve pressure detection and control during the friction stir welding process.

Real time measurement of the forging force on the front end of the stirring head during the welding process and feedback to the system.

The system receives feedback values for comparison and calculation, controls the Z-axis pressing amount, and forms a closed-loop control of the entire process.

Welding traceability system: IT supports data transmission to the upper computer and enters the MES system.

Hydraulic station and tooling interface:a new four circuit horizontal hydraulic station is added to the machine.

The maximum working pressure of the hydraulic station is 5MPa.

It is equipped with corresponding electromagnetic valves and 8 four circuit oil pipes, each with a length of 4m.

The pipeline is matched with the tooling, and the oil pipe is equipped with a drag chain in the X axis direction.

Relay circuit breakers and other necessary electrical components for hydraulic station control are equipped.

Gas detection system:Confirm whether the air source pressure value of the pneumatic tooling meets the working requirements by detecting the air inlet pressure;

By detecting the air inlet pressure, confirm the air tightness between the tooling and the work-piece, and whether the work-piece clamping meets the requirements.

Rapid cooling system: the system is connected with an external air source, which can provide cooling air flow below 5 ℃ to reduce the temperature of tooling and work-pieces.

Protective cover: it can be used to protect lead screw, light rod, column, main shaft and other circular rotating columns;

protect the internal hard guide rail, linear guide rail, ball screw or transmission rack of the FSW machine tool from external corrosion and damage.

To know more information about AEE, welcome to surf in the website: https://a-fsw.com/