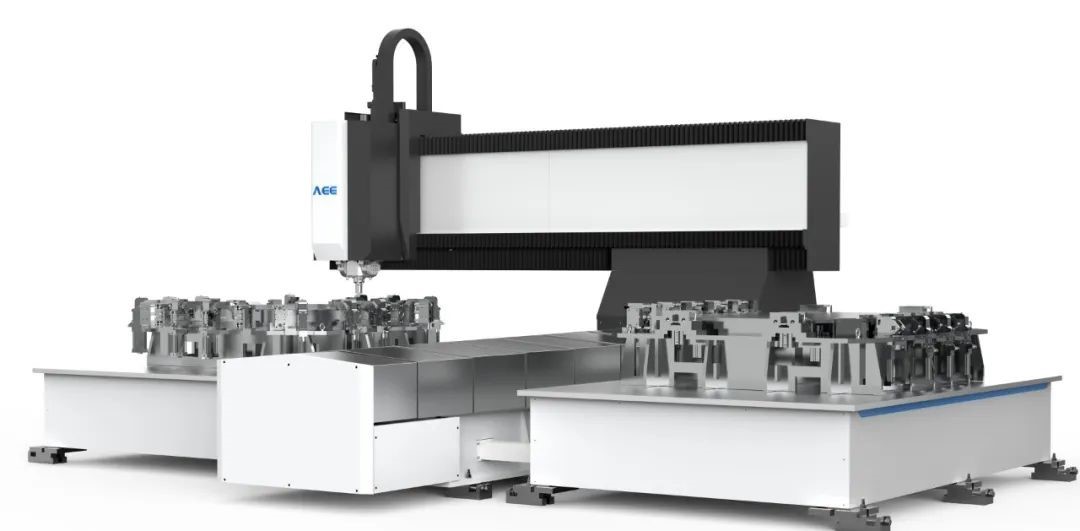

Cantilever Dual Station FSW Machine in China

Cantilever Dual Station Friction Stir Welding Machine——Meeting the needs of the field of new energy vehicle battery trays

Introduction

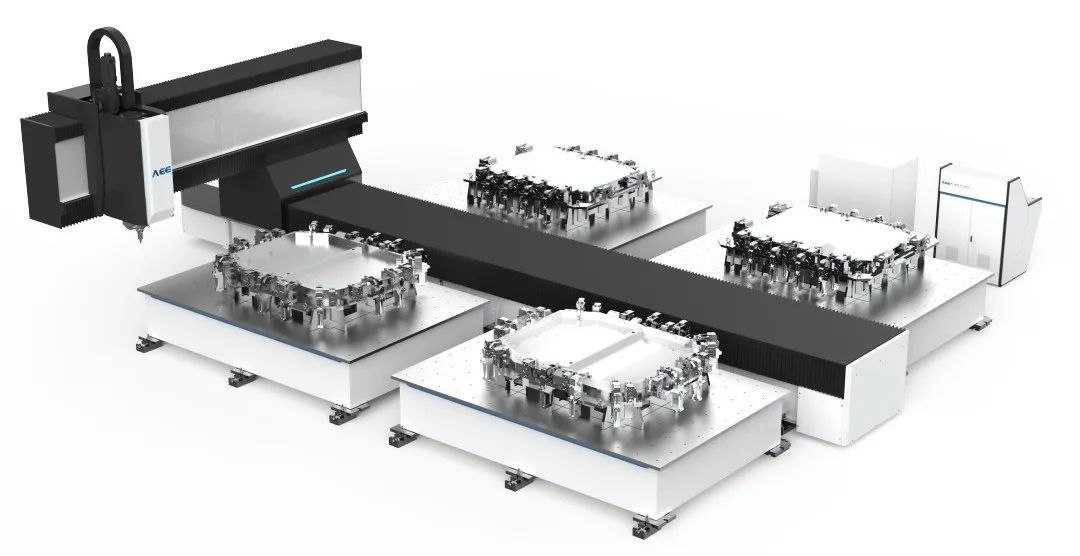

The cantilever dual station friction stir welding machine is a processing tool independently developed by AEE to meet the automation, intelligence, and flexibility production needs in the field of automotive battery trays.

Under the premise of fully considering weld quality and welding speed, break through the original equipment structure and layout to adapt to the diverse needs of product development.

Performance characteristics

The base of the cantilever dual station stirring friction welding machine is a four rail structure with excellent rigidity, and is equipped with a high rigidity and high torque mechanical spindle.

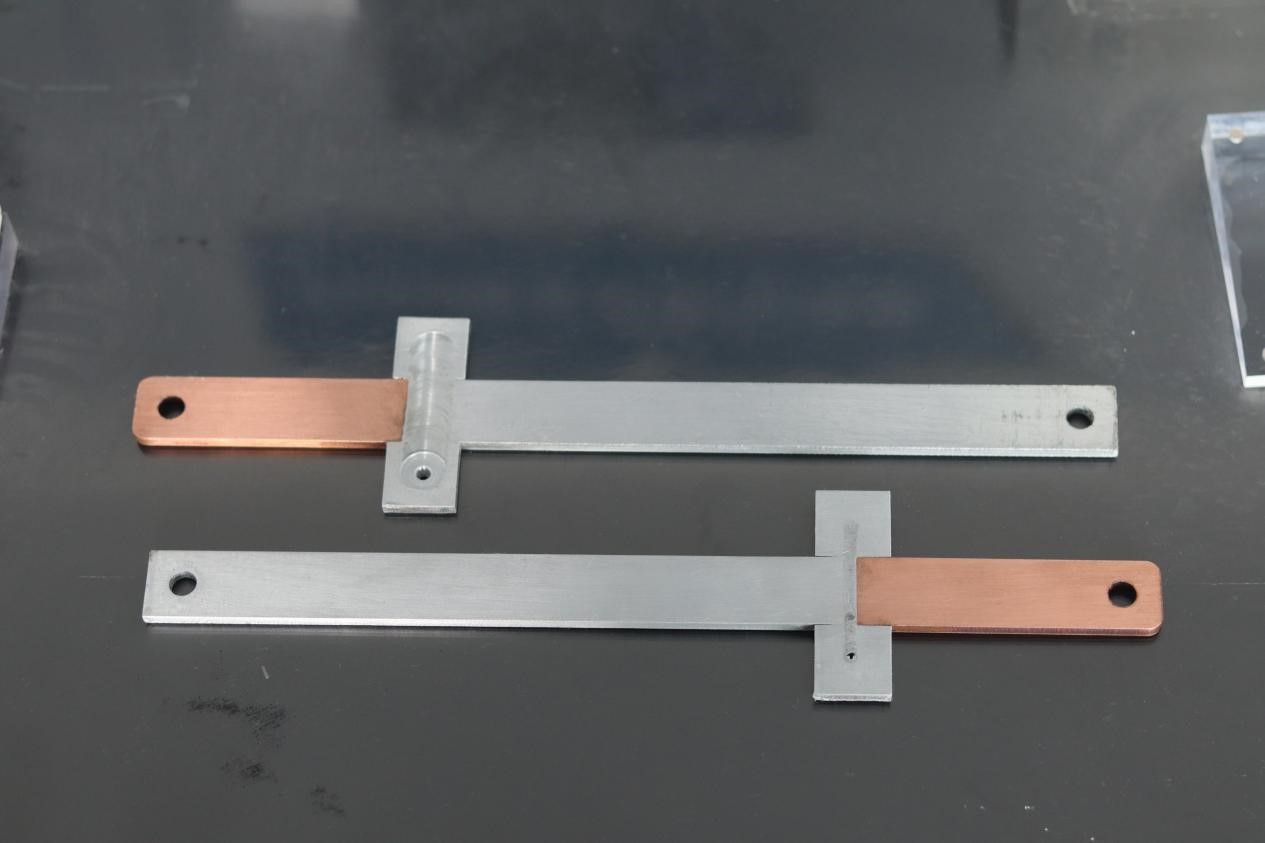

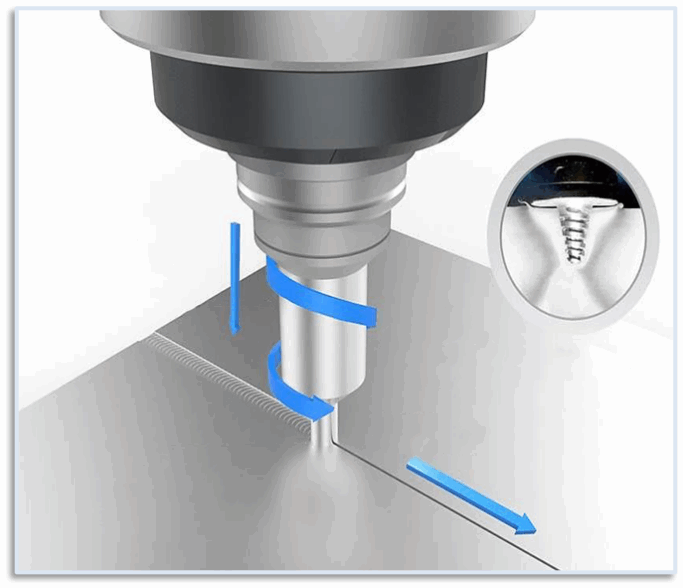

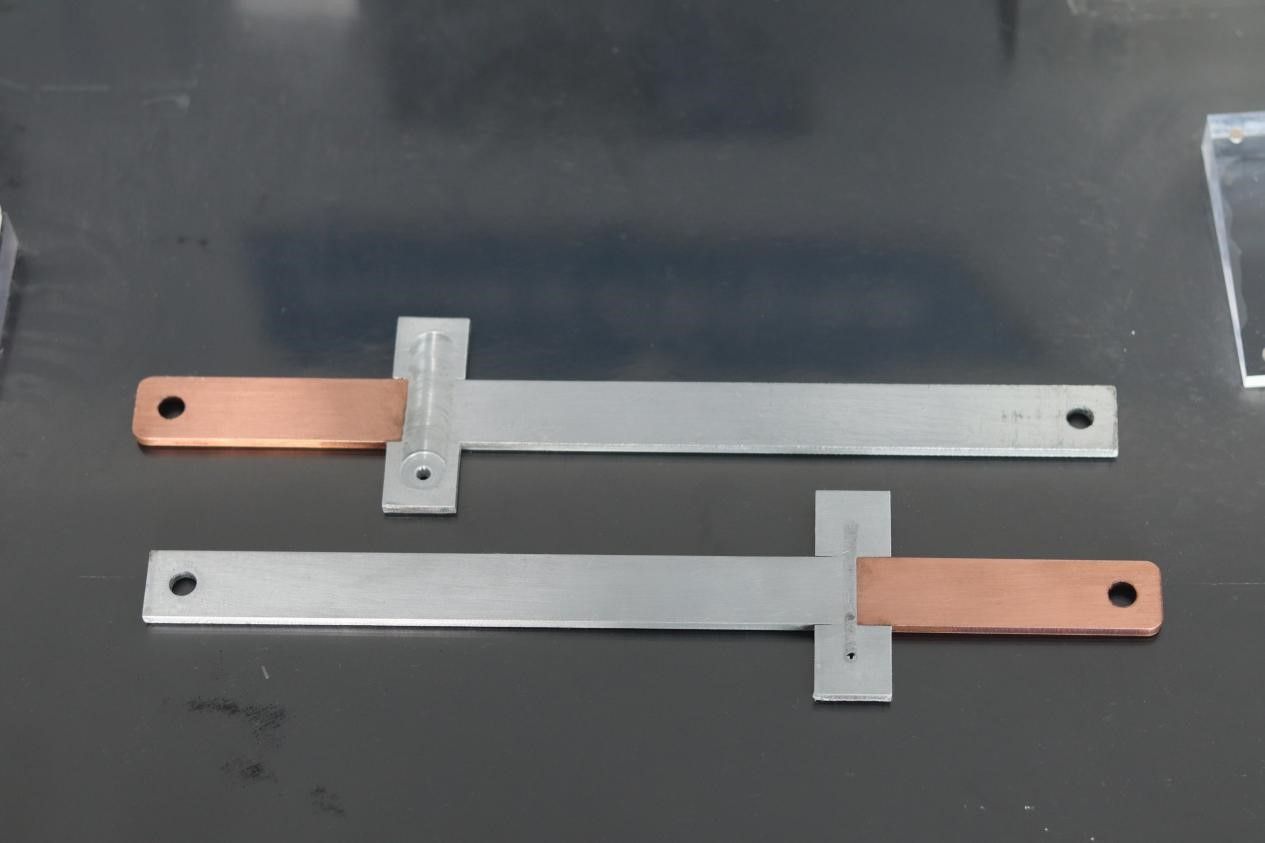

It is equipped with a self-developed static shoulder stirring head product and a constant pressure control system, ensuring the quality of the weld seam when welding the battery tray bottom plate and assembly.

The machine also has product traceability function, which can quickly read, save, analyze, and other welding parameters of the machine.

The device adopts a combination of a large floor mounted operation screen and a portable wireless hand-wheel/touch operation screen, facilitating close adjustment and observation, creating a high-end and user-friendly operating experience.

Structural characteristics

The main body of the machine adopts a cantilever structure, which has a high space utilization rate and saves about 35% of the land area compared to the gantry type friction stir welding machine.

Double station symmetrical layout, horizontal movement of the crossbeam to achieve welding station switching, with good flexibility;

The layout form of expandable dual head, multi station and multi beam can meet the needs of batch processing and further improve production efficiency.

The modular design of the tooling platform allows for easy switching, and can be replaced with floor mounted tooling.

It has higher flexibility and can adapt to the diverse needs of products.

It is also convenient to connect with robots, AGVs, and other intelligent factory transplant vehicles, perfectly realizing the intelligence, automation, and flexibility of special equipment for friction stir welding.

Technical specification

The equipment is used to achieve 2-6mm two-dimensional friction stir welding of various series of aluminum alloys, with a standard working platform size of 3m×2m, uniformly distributed M16 matrix holes, covering products and tooling combinations within 3m×2m×0.7m.

Equipment Model | AEE-FSW6×30/2S | ||

Welding Thickness | (mm) | Aluminum Max.6 | |

Working Table(W×L) | (mm) | 3000×2000 | |

Net Height | (mm) | 255-755 | |

Stroke | X axis | (mm) | 3000 |

Y1 axis | (mm) | 3220(Full stroke) /1800(Unilateral stroke) | |

Y2 axis | (mm) | 2460 | |

Z axis | (mm) | 500 | |

C axis | (。) | N×360 | |

B axis | (。) | 0-5 | |

Fast Moving Speed | X axis | (mm/min) | 10000 |

Y1 axis | (mm/min) | 8000 | |

Y2 axis | (mm/min) | 7000 | |

Z axis | (mm/min) | 3000 | |

Spindle Maximum Speed | (rpm) | 4000 | |

Machine Outline Dimension | (mm) | 7000×6500×3200 | |

Application

The machine is widely used in the mass production of lightweight alloy products in industries such as new energy vehicles, rail transit, and electronic power.

Its main products include new energy vehicle battery trays, base station radiators, electronic control boxes, water-cooling plates, and train heat dissipation plates.

About C-type Friction Stir Welding Machine, more information can be found on the website: https://a-fsw.com/